Category

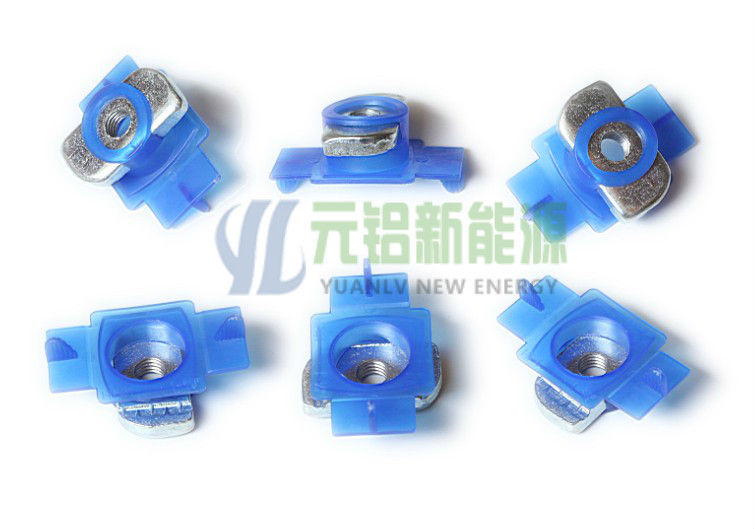

Guide rail connector-40 special rail

With rich esperience in aluminum processing ,good and fully automated production lines, a perfect supply chain ,and strict design and verification ,our products hao won national and international recognition and perference in a very short time. We have successfully provided high quality accessory photovoltaic products for many photovoltaic assembly enterprises ,photovoltaic surface power stations as well as photovoltaic roof power station projects.

Classification:

Rail connection

- Product Description

-

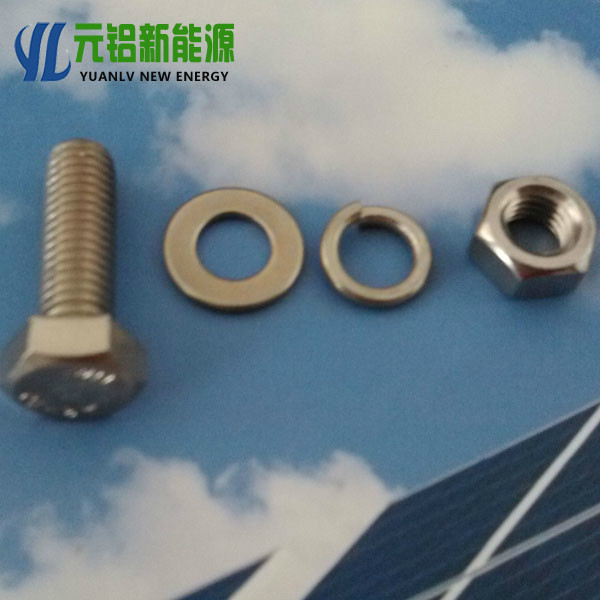

Product Details:Product name: guide rail connectionLength: 100mmMaterial: Aluminum alloy 6063-T5Surface treatment: Anodized AA10μmCompany Profile: Yuanlu New Energy is an aluminum profile manufacturing enterprise dedicated to providing aluminum frames and photovoltaic bracket mounting components for global photovoltaic modules and investors and general contractors of photovoltaic power plants worldwide. The company is composed of a team of senior aluminum extrusion and aluminum profile processing experience. The factory is located in China Aluminum Profile Industrial Base-Zhouzhuang Town, Jiangyin City, Jiangsu Province.The company has a powerful supporting enterprise with more than 10 years of experience in the global aluminum industry. The company's products have quickly achieved large-scale production, and the industry's resources have been integrated, from aluminum ingots, melt casting, extrusion, sand blasting, oxidation processes to fine cutting and stamping. And other complete industrial chains, bringing the most professional aluminum alloy profiles to Chinese customers. At present, it has an annual production capacity of 500,000 tons of aluminum profiles, and the annual production capacity of photovoltaic products reaches 300MW.With years of rich experience in aluminum profile manufacturing and processing, an efficient and professional R & D team, rigorous design concepts, sophisticated production lines, and complete supply chain support, Yuan Aluminum Solar Bracket quickly gained recognition and favor from domestic and foreign customers The photovoltaic ground power station and photovoltaic roof power station provide high-quality solar support products.honor certificate:The company's products have passed ISO9001: 2008 international quality management system certificationProduction process: batching → melting → casting → aluminum rod heating → extrusion → quenching → automatic sawing → stretching straightening → framing → aging → sandblasting → upper row → degreasing → alkaline etching → neutralization → anodizing → ( Coloring) → sealing (electrophoresis) → lower row → inspection → into semi-finished product warehouse → precision sawing → punching → packing → sticking certificate → deliveryOur advantage:Yuanlu New Energy mainly uses aluminum profiles to manufacture our photovoltaic mounting system. Compared with steel, aluminum profiles have the following advantages:l Light weightAluminum density 2.7kg / dm3Iron density 7.9kg / dm3l Resistance to natural corrosionAluminum placed in the air can form a dense aluminum oxide protective layer on the surface layer. This protective layer can prevent further oxidation of the aluminum material.l Anti-galvanic corrosionWhen the steel bracket is in contact with the aluminum photovoltaic panel frame, the aluminum photovoltaic panel frame is prone to galvanic corrosion, and the aluminum bracket avoids this phenomenon.l Balance voltageAluminum has excellent conductivity, so it can better conduct the weak current generated by various reasons in the photovoltaic mounting system.l Easy to formDifferent profiles can be used to easily obtain aluminum profiles with different cross-sectional shapes through the extrusion process.l Easy to processAluminum profiles can be easily processed to the required specifications through sawing, drilling, punching, folding and other processes, and the energy consumption of the processing process is much lower than that of steel.l Low temperature resistanceOrdinary steel, especially the welding area, is fragile and fragile in low temperature environments, while the strength of aluminum is increased.l Environmental protection and easy recyclingAfter recycling, the aluminum material only needs to consume 5% of the energy from the aluminum ore to the profile.Engineering case:

Key word:

PV bracket accessories series / Aluminum bracket series / Aluminum profile processing

Product Consulting

Related Products